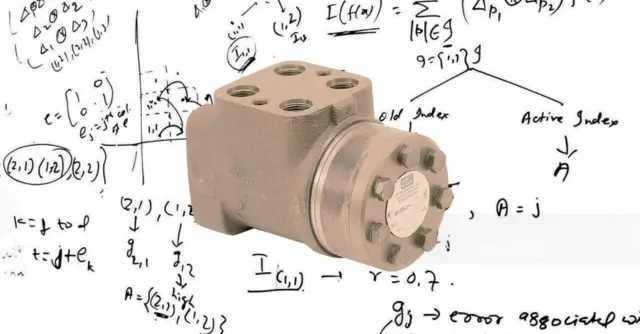

Hydraulic Steering Unit Displacement Calculation (Part 7)

Now that we’ve explored different types of steering systems, their components, and how they work, it’s time to bridge theory with practice. In this final post of our steering series, we’ll focus on calculating hydraulic steering unit displacement: a critical calculation that determines which steering unit is right for your machine and how well it […]