Last updated on June 8th, 2025 at 02:31 pm

Ever wondered what makes steering systems so adaptable across different vehicles? This post shows the inner workings of steering features like 2-Speed technology and Q-Amp flow amplification, showcasing how they transform vehicle control. Curious to know how they work?

In our previous post, we talked about the different types of steering units and what makes them unique. This time, We’ll look into how their circuits work and unique features that are tailored to specific applications.

Work Circuits of Steering

Non-Reaction Steering

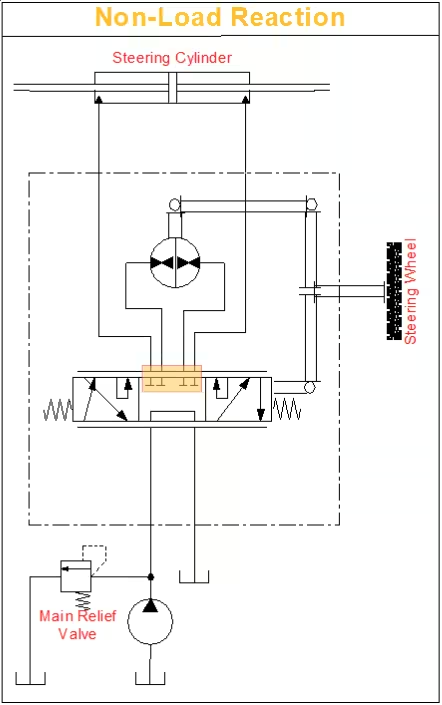

Non-reaction steering units are designed to keep the steering wheel steady when the driver isn’t actively steering. When the vehicle is at rest or the operator releases the steering wheel, the cylinder ports are blocked in the neutral position, locking the axle in place (Fig. 1). This ensures stability by holding the axle’s position firmly.

Reaction Steering

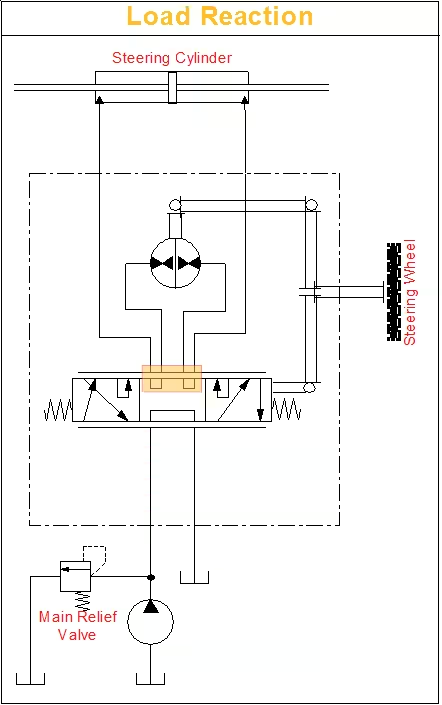

Reaction steering units work differently. Here, any external forces acting on the steered wheels cause a corresponding movement of the steering wheel, even when the driver isn’t steering. A load reaction steering unit connects the cylinder ports to the meter gear set in neutral, allowing axle forces to naturally return the steering wheel to its approximate original position (Fig. 2).

This mechanism is similar to what we experience in car steering—releasing the wheel mid-turn lets it spin back as the vehicle straightens. For this to work effectively, the cylinder system must have equal oil displacement in both directions. Typically, a parallel pair of cylinders or a double rod-end cylinder is used. Avoid using this setup with a single, unequal-area cylinder system, as it won’t provide the required balance.

Fig.1: Non-Load Reaction Work Circuit in Steering

Fig.2: Load Reaction Work Circuit in Steering

Features and Application

2-Speed Technology

2-Speed technology offers two operator-selectable metered modes. With the touch of a button or flip of a switch, operators can seamlessly switch between modes for optimal performance during roading and work cycles. The system uses two gerotors:

- The first gerotor is smaller and handles standard steering tasks during normal operation.

- The second gerotor is activated via a shift valve, which is controlled by a solenoid valve.

The OEM provides the switch to activate the solenoid valve, allowing smooth operation between the two steering modes.

- Metered Steering Mode 1:

- Functions like a traditional hydrostatic steering unit, offering 4-6 turns lock-to-lock.

- Steering flow is proportional to steering wheel rotations (RPM).

- All flow is metered by the first gerotor.

- In the event of pressure loss, the shift valve blocks flow to the second gerotor, ensuring emergency steering through the first gerotor.

- Metered Steering Mode 2:

- Ideal for tasks requiring rapid and responsive steering, with two or fewer turns lock-to-lock.

- Steering flow remains proportional to steering wheel rotations, but the number of turns lock-to-lock is significantly reduced as low as 0.5.

- The displacement ratio between gerotors can range from 1:1 to 5:1, offering design flexibility.

- Combines the displacement of both gerotors for increased flow, significantly reducing operator effort and enhancing efficiency during intensive operations.

Advantage

- Emergency Steering: Maintains manual steering capability in unpowered mode.

- Proportional Flow: Steering flow always corresponds to the speed of steering wheel rotations.

- Versatility: Excellent road handling with quick-steer options for work cycles.

Feature

- Open Center, Load Sense system.

- All integral valves for reliability.

- Wide-angle functionality.

- Maximum system pressure: 241 Bar (3500 psi).

Application

This technology is ideal for a variety of equipment and vehicles, including:

- Ackerman Steering Systems.

- Tractors, telehandlers, sweepers, forestry equipment.

- Backhoes, loaders, sprayers, combines, motor graders.

Q-Amp Flow Amplification

Q-Amp Steering Control Unit (SCU) provides a significantly higher volume of steering oil compared to traditional SCUs of the same size. This increased flow is achieved when the steering shaft rotates at higher speeds, such as 10 rpm or more.

Unlike 2 Speed Features, this Q-Amp doesn’t need button or flip of a switch.

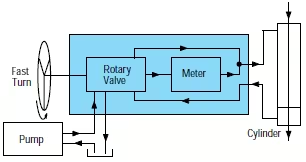

Q-Amp steering units utilise built-in variable orifices to optimise flow directly to the cylinder without routing it through the gerotor section. These orifices only open after the gerotor starts rotating, gradually increasing flow until the desired rate is achieved. For instance, a typical Q-Amp unit with a 1.6:1 ratio delivers 1.6 times the flow through the cylinder compared to the gerotor at medium to fast steering speeds.

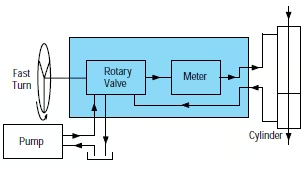

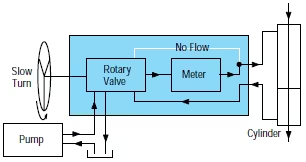

A conventional steering control unit routes all hydraulic oil through the rotary valve and meter, even during fast turns.

During fast turns, the Q-Amp SCU also uses variable orifices to bypass the meter, delivering more hydraulic oil directly to the cylinder.

For slow turns, the Q-Amp SCU routes all hydraulic oil through the meter while variable orifices remain closed.

(Image Source: Danfoss)

Advantage

- Compact Design: A smaller SCU can deliver a higher volume of steering oil.

- Smooth High-Speed Steering: When traveling at high speeds, the SCU remains stable and less reactive, even with slow steering wheel movements.

- Fast Turns: Allows for quick and responsive turns when the steering wheel is rotated rapidly.

- Manual Steering: In cases of engine power loss, manual steering can be difficult with large displacement SCUs. The Q-Amp addresses this by combining the smaller displacement needed for manual operation with the higher flow requirements for power steering.

Feature

- Single Cylinder (Unequal Area): On vehicles with a single unequal area cylinder, steering wheel turns may differ between directions. Extending the rod might require more turns than retracting it. Q-Amp units can incorporate a different flow ratio for each direction, ensuring equal turns lock-to-lock.

- Use Cases:

Ideal for articulated vehicles like wheel loaders, log skidders, scrapers, and trucks. For example, quick steering is essential for log skidders in the woods, while smooth and precise steering is crucial on roads. The variable ratio feature adapts to both scenarios, providing efficient steering in all conditions.

- Use Cases:

- Variable Ratio Steering

- The variable ratio feature adjusts steering flow based on the input speed of the steering wheel.

- Slow Input: Prevents overcorrection for smooth operation.

- Fast Input: Delivers additional flow for quick directional changes.

- The variable ratio feature adjusts steering flow based on the input speed of the steering wheel.

Application

Q-Amp delivers unmatched performance, making it ideal for vehicles that demand precision, adaptability, and reliability across diverse applications and terrains.

- Variable Ratio Steering:

- Wheel Loaders

- Scrapers

- Articulated AG Tractors

- Articulated Dumpers

- Mine Trucks

- Forestry Equipment

- Rough Terrain Lift Trucks

- Variable Ratio with Manual Steering:

- AG Tractors

- Small Wheel Loaders

- Rubber-Tired Excavators

- Sprayers

- Site Handlers

- Graders

- Combines

Wide Angle

Smoother Steering for Articulated Vehicles

Wide-angle SCUs are specifically designed for large articulated tractors to smooth out the bumpy and jerky steering motion commonly experienced with articulated steering systems. This is achieved by increasing the deflection between the SCU’s control spool and sleeve during turns, resulting in more refined and predictable handling. By increasing the maximum deflection of the spool relative to the sleeve, these units reduce the gain, which in turn lowers acceleration and jerk levels. Despite this reduction, the steering remains responsive enough for operators to feel in control, ensuring a seamless and efficient driving experience.

Standard Steering vs Wide Angle Steering

Advantage

- Improved Comfort: Dramatically reduces lateral jerking, enhancing operator comfort and control.

- Cost Efficiency: Simplifies hydraulic systems by eliminating the need for additional components like accumulators and cushion valves.

Feature

- Smoother Steering: Minimizes jerking motion, particularly on medium and large articulated vehicles.

- Simplified System Design: Eliminates the need for jerk-reducing valves and accumulators on most vehicles, leading to cost savings.

- Enhanced Dynamics: Reduces lateral jerk by up to 50%, delivering superior vehicle handling and comfort.

Application

Wide-angle SCUs are a game-changer for articulated vehicles, offering the smoothest steering experience for applications such as:

- Large Articulated Tractors

- Wheel Loaders

- Forestry Equipment

- Construction Vehicles

Cylinder Dampening

Enhanced Stability for Articulated Vehicles

Cylinder dampening SCUs are engineered to refine the steering performance of large articulated vehicles, such as tractors, loaders, scrapers, and skidders. These units achieve smoother motion by using adjustable orifices that divert a small amount of hydraulic fluid from the steering cylinder ports back to the reservoir during steering. This dampening action dissipates the energy generated by high inertial loads, particularly in vehicles with overhanging weight, ensuring more stable and controlled handling. As a result, the steering action becomes smoother, reducing the jerky motion often associated with articulated vehicles.

Advantage

- Improved Comfort: Provides a smoother and more predictable steering experience for operators.

- Enhanced Vehicle Dynamics: Stabilises steering systems, especially under high inertial loads.

- Versatile Application: Perfect for vehicles handling rugged terrains and heavy overhanging loads.

Feature

- Smoother Steering: Minimises jerking motion in medium and large articulated vehicles.

- System Stability: Damps or stabilises steering systems prone to instability or excessive vibration.

- Energy Dissipation: Effectively dissipates energy from high inertial loads, improving vehicle control.

Applications

Cylinder dampening SCUs are ideal for heavy-duty articulated vehicles that require precise and stable steering, including:

- Wheel Loaders

- Scrapers

- Skidders

A detailed use of these features can be found on multiple machinery through the Danfoss Portfolio.

Patent for a Technology

Q-Amp Flow Amplification

Steering Control Unit with Flow Amplification

Steering Control Unit with both Flow Amplification and Manual Steering Capability

Fluid Controller and dampening Fluid Path

Wide Angle and Cylinder Damping

Large deflection angle rotary modulation steering valve

Conclusion

Modern steering systems have come a long way, evolving to meet the unique demands of various applications. Whether it’s the steady control of non-reaction circuits or the intuitive return-to-center feel of reaction circuits, these technologies are designed with operators in mind.

Innovations like 2-Speed Technology and Q-Amp Flow Amplification take things even further, offering seamless adaptability between precision and efficiency. Wide-angle SCUs and cylinder dampening ensure smoother, more comfortable handling, even in challenging environments.

What’s Next?

So far in our steering series, we have covered:

Post 1:

We explored the application of steering units, their components, and the various design elements that make up a steering system.

Post 2:

We examined different types of steering units, including open center, power beyond, and closed center systems, and explored load sensing circuits with static and dynamic signal systems.

🚀 Coming Up Next (Post 4):

We will focus on the steering control unit’s spool-sleeve mechanism. We’ll break down how the steering unit operates in different modes, including 4-wheel steer, crab mode, and 2-wheel steer mode.

If you enjoyed this post, I’d really appreciate it if you could subscribe. I’m 100% planning to dive deep into hydraulics and break it down into simple terms for you!